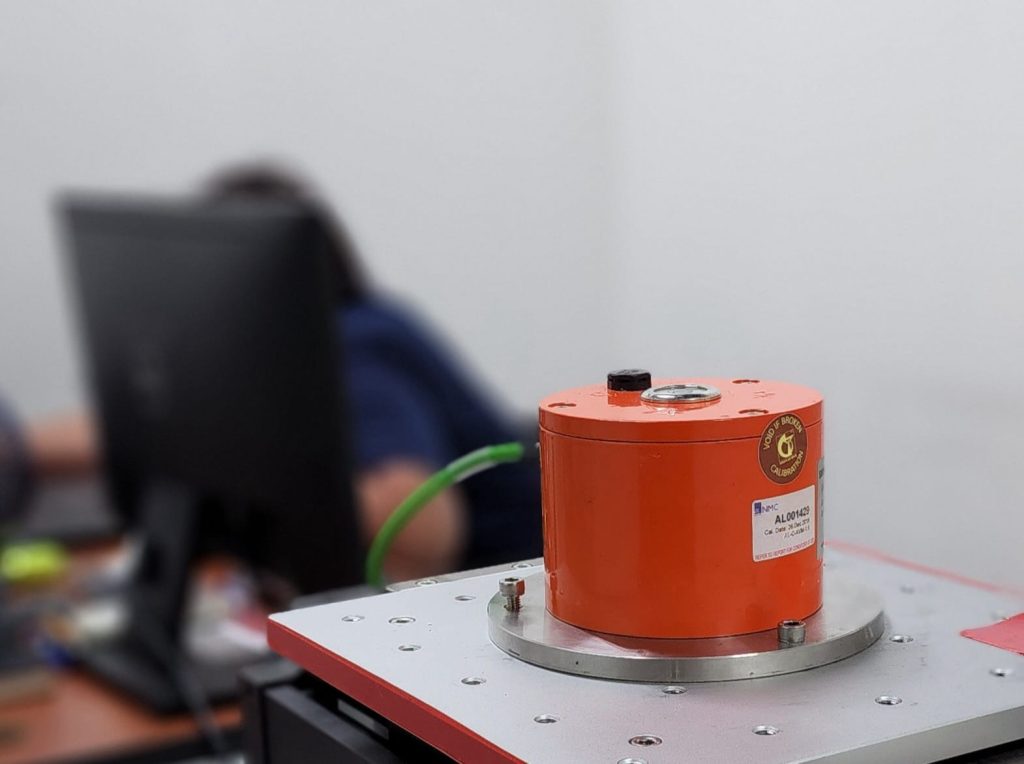

Accelerometers play a crucial role in numerous applications across various industries, ranging from aerospace and automotive to consumer electronics and robotics. These devices measure acceleration forces, enabling us to understand motion, vibration and orientation. However, to extract reliable and precise data from accelerometers, mastering their accuracy is of paramount importance. The journey from the calibration lab to achieving precision results involves a meticulous process that demands attention to detail and adherence to best practices. The first step in mastering accelerometer accuracy is calibration. This initial process involves subjecting the accelerometer to known reference forces under controlled conditions. Calibration ensures that the device’s output corresponds accurately to the applied forces, thus establishing a baseline for future measurements. The calibration lab employs highly sensitive equipment, traceable standards and advanced procedures to minimize uncertainties and errors during this critical stage. Regular calibration checks are essential to maintain accuracy over time, as environmental factors and wear can impact the device’s performance.

Next, proper handling and storage are crucial to preserve the calibrated state of the accelerometer. These devices are sensitive to extreme temperatures, humidity and mechanical shocks. Therefore, it is imperative to follow the manufacturer’s guidelines and handle the accelerometer with care. Specialized protective casings and storage solutions help safeguard the device when not in use, ensuring its accuracy remains intact. One of the key challenges in accelerometer accuracy lies in compensating for external factors that can influence measurements. Cross-axis sensitivity, temperature fluctuations and electromagnetic interference are among the common culprits. Advanced calibration techniques, including temperature compensation algorithms and multi-axis calibration setups, help minimize these effects. Furthermore, shielding and grounding techniques are employed to mitigate electromagnetic interference, enhancing the device’s accuracy in complex environments. Translating raw data from the accelerometer into meaningful and precise results involves sophisticated signal processing techniques.

Filtering algorithms, such as low-pass and band-pass filters, help remove noise and irrelevant frequencies from the ats labs measurements. Additionally, advanced mathematical models and data fusion algorithms may be employed to combine data from multiple sensors, further enhancing the accuracy and reliability of the results. As technology continues to evolve, new opportunities for improving accelerometer accuracy arise. Cutting-edge sensor designs, such as microelectromechanical systems (MEMS), offer enhanced precision and reduced power consumption. Furthermore, the integration of artificial intelligence and machine learning algorithms empowers accelerometers to adapt and optimize their performance based on real-time data, providing unparalleled accuracy in dynamic environments. In conclusion, mastering accelerometer accuracy is a multi-faceted process that begins with meticulous calibration in specialized labs. Careful handling and storage, along with robust compensation techniques for external factors, help maintain the device’s accuracy over time. Advanced signal processing and data fusion algorithms enable the translation of raw data into precise results. Embracing emerging technologies and innovations further enhances accelerometer accuracy, paving the way for groundbreaking advancements in industries and applications worldwide. As these devices continue to evolve, their impact on modern technology will undoubtedly become even more profound.